Fastener washers are a kind of parts used between the supporting surface of bolts, screws or nuts, etc. and the parts to be connected, the main role is to increase the contact area, spread the load, reduce the pressure, prevent the fasteners from loosening, leakage and damage, as well as to ensure that the reliability and sealing of the connection. According to the shape, material and use of different, fastener washers can be divided into a variety of types.

Flat Washers

Flat washers are the most commonly used type of washers, the shape is mostly round, but also according to the assembly needs of other shapes, such as square washers.

Mainly used in general bolts or screws connection, to increase the contact area, improve the force condition and protect the surface of the connected parts of the role.

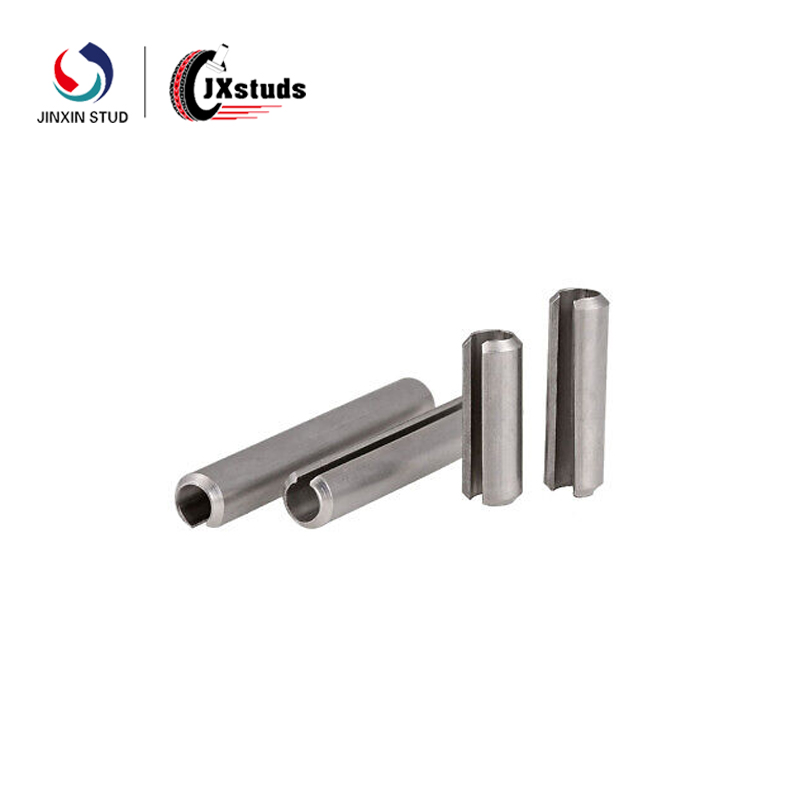

Spring Washers

Standard spring washers are spiral in shape and have openings. In addition to standard spring washers, there are also light spring washers, heavy spring washers, wave spring washers, conical elastic washers, saddle spring washers and so on. They are mainly used in the load-bearing and non-load-bearing structures of mechanical products, especially the parts that are frequently installed and disassembled. Low cost, easy to install, can provide additional pressure and fastening force.

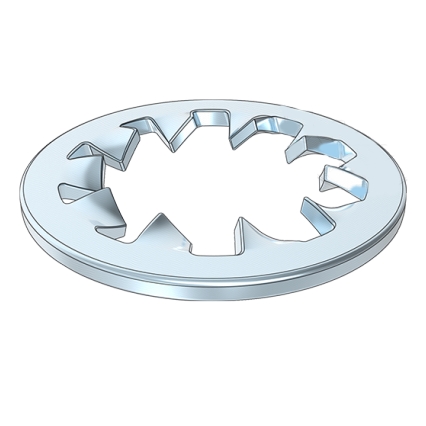

Lock washers

Lock washers are mainly used to realize locking purpose by increasing friction. Commonly, there are SK tooth self-locking washers, double-sided lock washers, internal tooth lock washers, internal serrated lock washers, external tooth lock washers, external serrated lock washers and so on. Internal/external tooth lock washers rely on the tooth tip and the plane of the connected part of the meshing force and a small elasticity to prevent the threaded connection loosening.

Stop Washers

Mainly used to prevent fasteners from loosening or falling off in vibration, shock and other environments. Including single lug stop washers and double lug stop washers and other types. Single lug stop washer by the inner ring, outer ring and one side of the ear piece composition, the main role is to prevent liquid or gas leakage, while providing axial and radial fixed support. Double lug stop washer often spring steel or stainless steel, the main role is to prevent the bearing in the working process of axial displacement.

Special Shape Washers

Such as wave washers (wavy, with good elasticity and shock absorption properties, suitable for vibration equipment and electronic equipment, etc.), spherical washers, square beveled washers (for I-beam connections), etc.