In the realm of automotive suspension systems, king pins and ball joints play crucial roles as a regular hardware parts fasteners. However, they have distinct characteristics that set them apart.

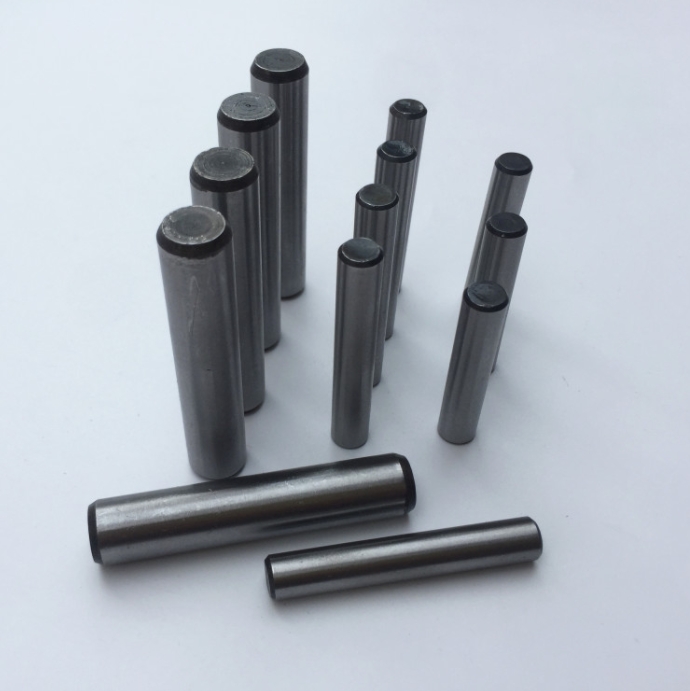

The king pin is a large pivot pin that serves as the axis around which the steering knuckles rotate. It is a key component in older vehicle designs. One of its main features is its durability and strength. King pins are often made of hardened steel to withstand the heavy loads and stresses of steering and suspension movements. They offer a more rigid connection between the wheels and the vehicle frame. However, maintenance of king pins can be more complex and time-consuming. They require regular greasing and inspection to ensure proper functioning.

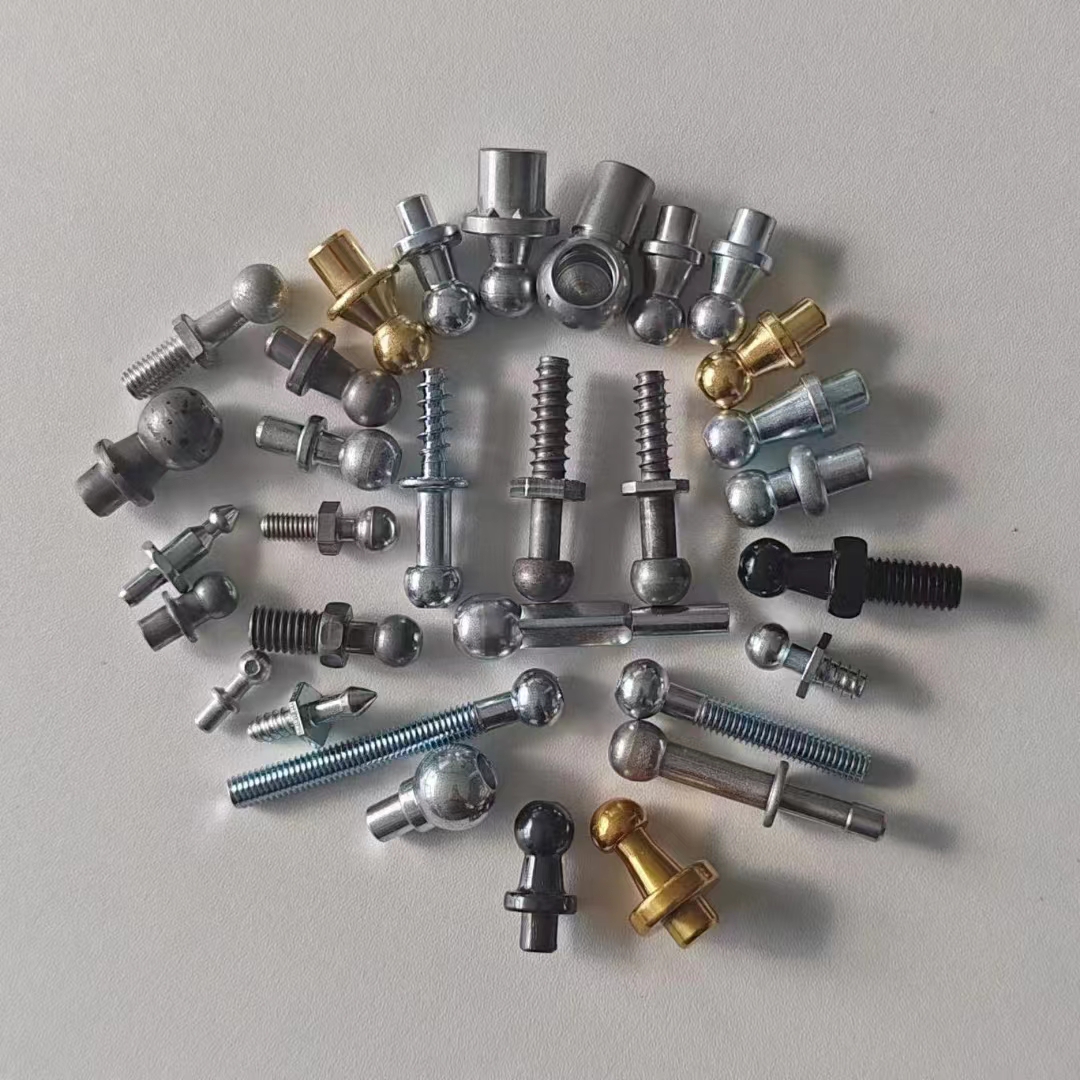

On the other hand, ball joints are spherical joints that connect the control arms to the steering knuckles. They provide a greater degree of flexibility and allow for a wider range of movement. Ball joints are designed to handle the up-and-down and side-to-side motions of the wheels. They are typically made of high-strength materials and are sealed to prevent dirt and moisture from entering. Maintenance of ball joints is relatively easier as they are often replaced as a unit when worn out.

In terms of performance, ball joints offer smoother steering and better handling. They can adapt to different road conditions more effectively, providing a more comfortable ride. King pins, while sturdy, may not offer the same level of smoothness and flexibility.

In conclusion, king pins and ball joints have their own unique characteristics and functions. While king pins are more common in older vehicles and offer durability and strength, ball joints provide flexibility, ease of maintenance, and better performance in modern automotive suspensions.

If any question or more profesional explaination welcome to have a disscussion and sharing.

Jinxin Group- Fastener Overseas Business

wendy Liu