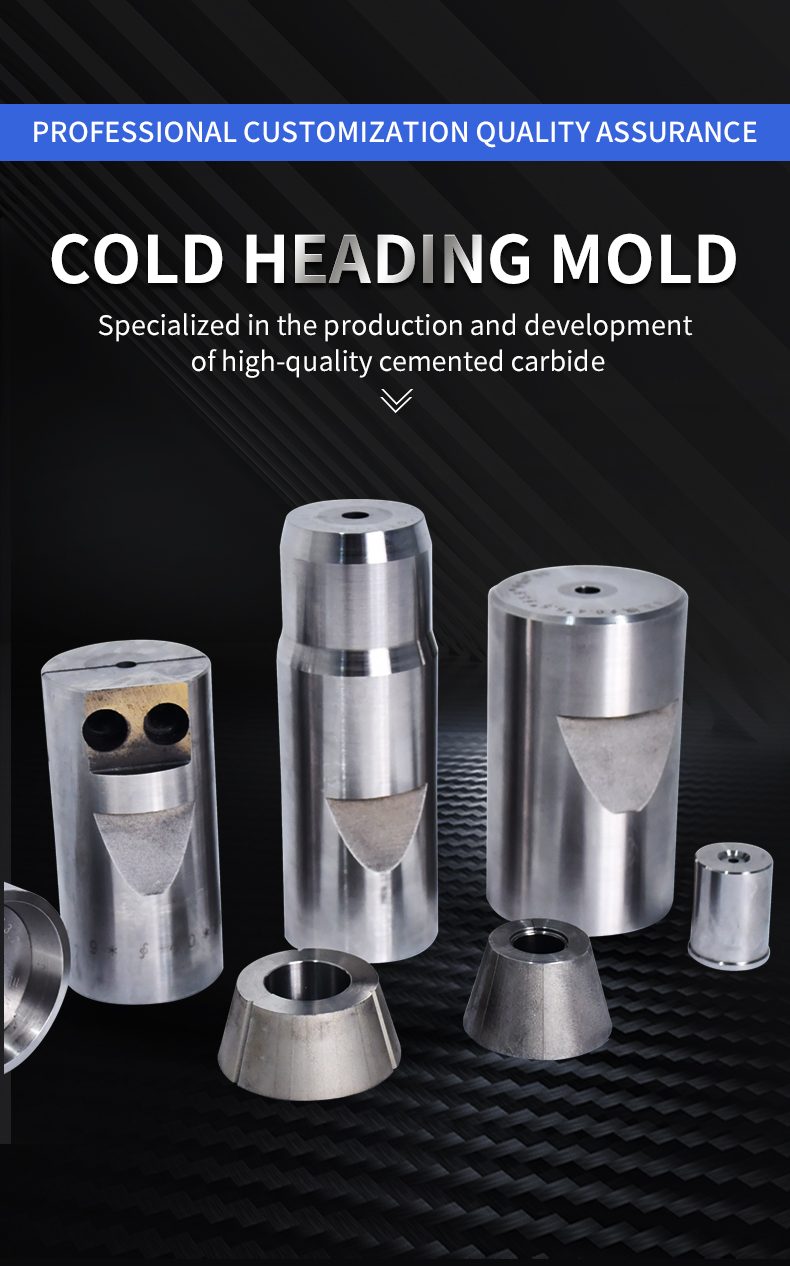

Cold Heading Mould Manufacturer cold forging mold

Main components and material selection of cold heading molds

1. Main components of cold heading molds: Cold heading molds mainly include upper and lower molds, mold cores, and mold seats. The upper and lower molds are used to clamp metal materials and complete the forming process through the clamping action, while the mold core is used to support and form the internal structure of the material.

2. Material selection for cold heading molds: The materials for cold heading molds need to have high hardness, high strength, good wear resistance, and fatigue performance. Common cold heading die materials include alloy steel

High speed steel, hard alloys, etc.